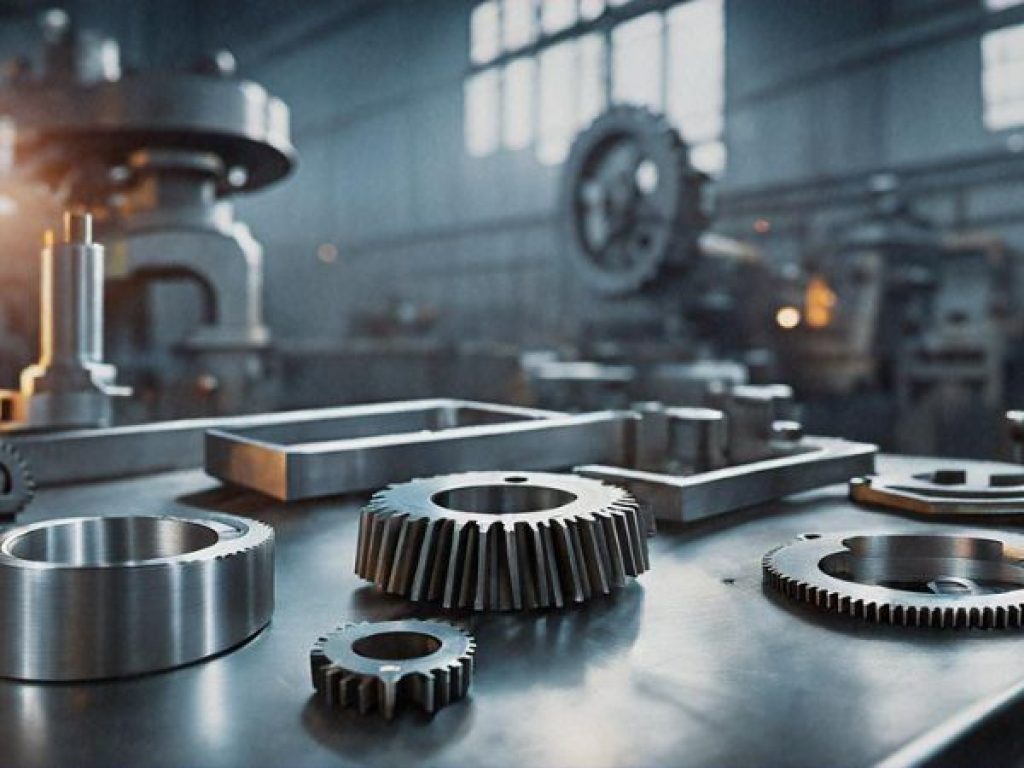

Modern forging processes have come a long way from the days of ancient warriors’ swords and the crankshafts in today’s vehicles, but they still follow the same basic rules. This blog will look at the field of forging, including how it works, the numerous techniques utilised, and why it is still important in today’s industrial environment.

Table of Contents

The Roots of Modern Forging Techniques

The history of metal forging is closely linked to the history of civilisation. Early people learnt that heating metal made it easier to shape, so they could hammer it into the forms they wanted. These early methods, which probably started in the Copper Age about 5,000 BC, are what led to the forging methods we use today.

The Industrial Revolution: Using Old Knowledge on a Large Scale

The Industrial Revolution made a huge difference in the world of forging in the 18th and 19th centuries. But even then, the backbone was old information that had been used in new devices. Steam-powered hammers took the role of human work, and factories could make a lot of forged pieces. While crafting was still a huge job, many Craftsmen continued to forge items using methods that they had used for centuries to form, heat and cool the metals.

Today, Forging has moved beyond the development of weapons, as Forging now also includes the manufacture of train, engine and bridge components, etc. Therefore, forged metals were an important component of heavy-duty applications due to their high strength.

New Technology with Old Knowledge

Computer-aided design, electric furnaces, and precision material science are all used in today’s forging procedures. But at their foundation, they are just copies of ancient ideas: heat, change, cool, and refine. Open-die forging and impression-die forging are examples of techniques that have been used in the past.

In modern times, engineers do exactly what the blacksmiths of the past did – through algorithms, imitations and sensors. The only difference is that while the process of producing something has changed over time, the quality of work has remained constant as well as the level of care and respect given to the material being worked with.

The Different Kinds of Modern Forging Methods

There are a number of distinct current forging supplier India that follow different methods, each of which is best for a certain job and has its own set of benefits. Here is a list of the most prevalent ones:

Hot Forging: Hot forging is a type of forging which is very common method used by forging units. Here we heat the metal to just bellow its melting point. The metal becomes very soft and may be moulded easily with hammers, presses, or other machines while it is in this condition. Hot forging works with many types of metals and alloys, and it can make complicated forms with excellent dimensional precision.

- Open-Die Forging: This method employs tools that are not limited, unlike closed-Die forging. Craftspeople with a lot of experience shape the metal by hitting it with hammers and moving it between flat or particularly shaped dies. This approach lets you make more distinctive forms or shapes that are too big for closed dies, but it demands more ability from the person using it. Many customers use open-die forging for the creation of larger components, such as blocks, rings and ingots.

- Isothermal forging is a method of forging that maintains the temperature of the metal during the entire forging cycle. Induction heating of both the tool and the metal billet is the normal means of achieving this. Keeping the temperature steady lowers the chance of breaking and makes sure that the forged part has the same material qualities all around. Isothermal forging is great for high-strength alloys and uses that need very high performance.

- Cold forging: It is a method of forming metal at ambient temperature. The metal is usually pre-lubricated to make it easier to shape and decrease friction. People usually employ cold forging to make smaller, simpler forms out of certain metals that can handle the high pressures needed. This method has a lot of benefits, such as rapid production rates, great dimensional accuracy, and a nice surface quality. But it can only be used on particular metals and forms since it needs a lot of strength to shape them.

- Closed-die forging uses carefully machined dies to mould metal into complicated geometries. A hot workpiece is compressed within a closed chamber and forced to press up against the tool to replicate the complexity of the shape. In addition to a high degree of precision and consistency in production, this method is well suited for producing large quantities of intricate parts such as gears or cranks

- Ring Roll Forging: Ring rolling is a unique way to produce circular parts without seams (i.e., clean cut). A heated ring-shaped piece of metal is fed between rollers that turn in opposite directions and have grooves that slowly form the ring. This method makes high-quality rings that are almost the right form and have great strength for bearings, gears, and pipelines.

Thus many forging supplier companies are dedicated to giving you the best service and the best forged goods so that your business runs smoothly and effectively.